Automated Assembly Operations

Possibilities of Automated Assembly Operations with KINALI

By automating assembly operations, you can refine and improve your production. Thanks to robots, you can rely on the flow of the production line, precisely performed tasks and minimising material losses. By producing without unnecessary errors, you will increase the company's overall efficiency.

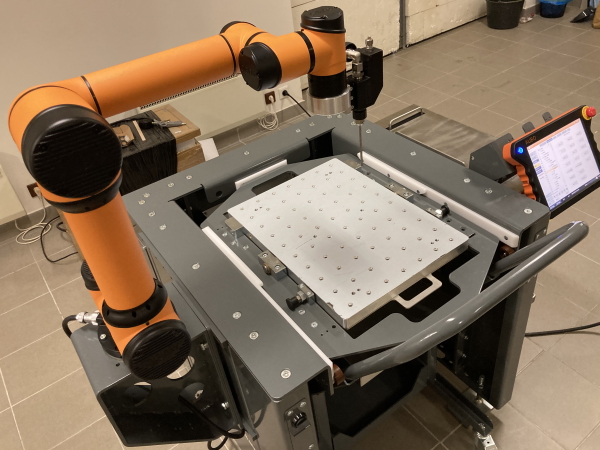

Our collaborative AUBO robots are popular in engineering production for their flexibility and ability to work 24/7. Whether welding, screwing or demanding work in a risk environment, we will program your cobots so that they always do their job reliably and on time.

What products can be assembled automatically

Our collaborative AUBO robots take up less space than humans and can work horizontally or be attached to the ceiling when needed.

AUBO cobots can handle virtually any production or assembly operation. We have experience with successful robotisation of operations such as screwing, welding, handling or cleaning parts. All of these operations are monotonous work that unilaterally strains the human body. In this respect, automation is a liberation not only from an economic viewpoint, but mainly from the viewpoint of workers' health.

Leave the stereotype to robots, people can do more meaningful work

| Human NO! | Cobot AUBO Yeah!!! |

|---|---|

|

Loses efficiency in repetitive activities |

Does not make mistakes in monotonous work |

|

In case of dangerous work, needs protective equipment |

Can work in risk environments |

|

Needs breaks for lunch, sleeping and vacations |

Works without breaks 24/7 |

| Training takes time |

Learns new things in a minute |

| Is subjected to environmental influences - assists colleagues around, solves unexpected situations and problems | Stubbornly focuses on its task |

Automation Options and Industry 4.0

KINALI robotic systems provide data connection to any superior ERP or MES system. Our collaborative robots respond precisely in the spirit of Industry 4.0 to the stimuli of other production nodes, can provide necessary information about their production cycles, provide statistics or automatically back up data.

The scalability of individual production nodes and their mutual connectivity brings higher efficiency and objective data from production. The advent of Industry 4.0 is becoming commonplace around the world. Those who get a head start in robotisation will be more competitive in globalised modern industry.

AUTOMATED ASSEMBLY OPERATIONS ENSURE

Financial savings

Have you calculated how much you spend on complaints per year? From now on, you can throw all your worries away.

Stable production

You will produce without downtime and delays. Precise calculation of the delivery date before each order.

Less error rates

Precise product handling and optical quality control reduces scrap to zero.

Satisfied employees

Your employees will be spared demanding repetitive activities, often in a risk environment.

MENU

MENU