Dimension Control

Possibilities of dimension control in KINALI

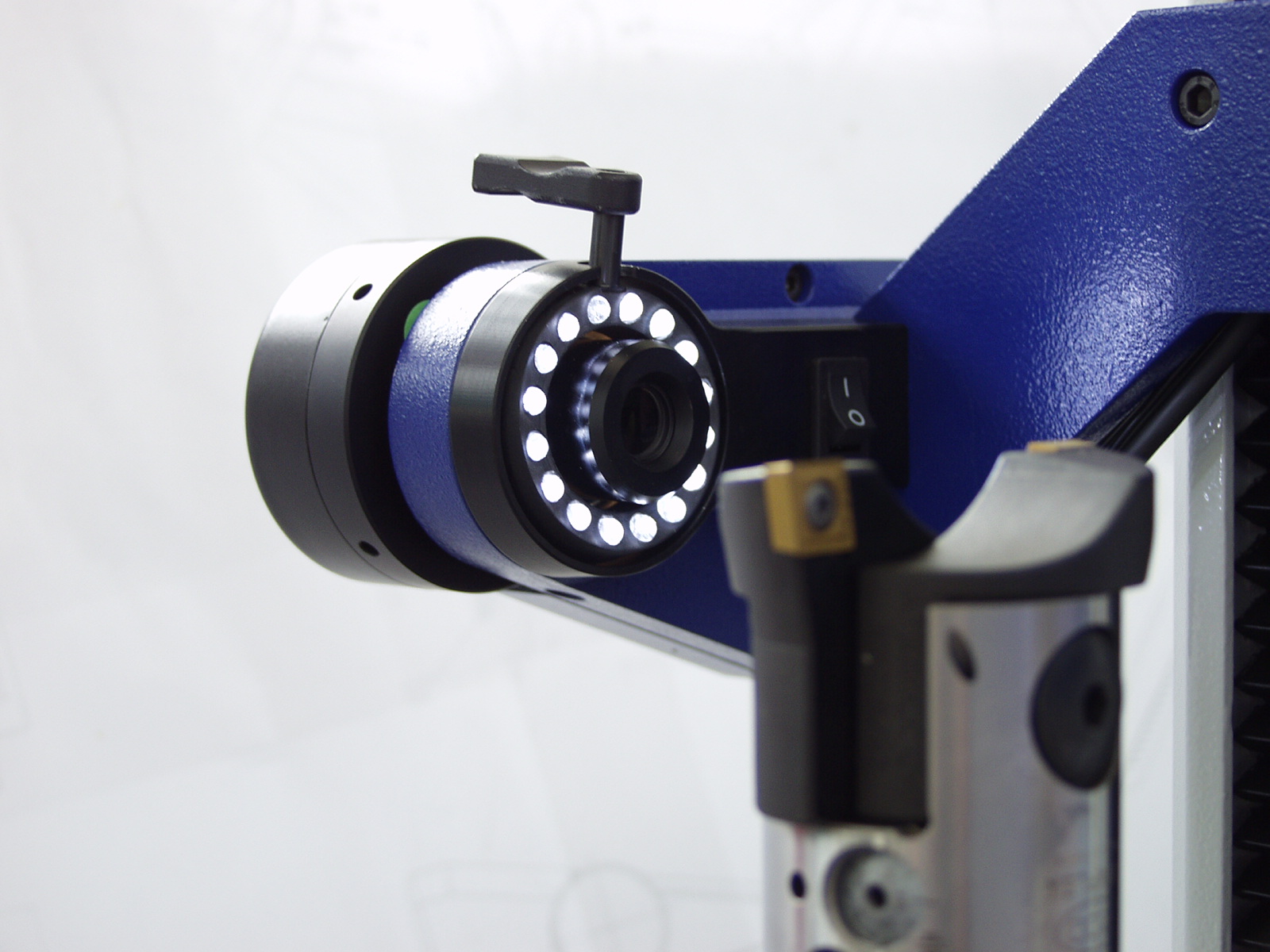

Product dimension control is one of the basic tasks in mechanical engineering. We are able to offer our customers universal tools for dimension control of products. Our measuring devices always work optically, i.e., without contact. At measurement speeds in the order of milliseconds, our devices achieve accuracy in micrometres. The aim is to speed-up the whole process as much as possible, therefore enabling measuring a larger number of products over the same period.

For measurements, we use only VICO telecentric lenses and illuminators, which guarantee the highest quality optical parameters. Based on the customer's specific requirements, we can place the cameras on the measuring device to cover the dimensions of any product.

What products can be measured optically

- Large parts and small precision components

- Products of all shapes

- Every circumferential dimension can be measured

Leave the stereotype and challenging tasks to the machines, people can do more meaningful work

| Human NO! | Optical control system Yeah!!! |

|---|---|

|

Accurate measurement in the order of mm |

Accurate measurement in the order of um |

|

Dimension control in the order of seconds |

Dimension control in the order of milliseconds |

|

Measurement repeatability in the order of tenths of mm |

Measurement repeatability in the order of thousands of mm |

| Suffers from fatigue |

Always works with the same alert |

| Needs breaks, vacation ... | Works constantly |

| Needs constant training and refreshers in case of changes | In case of changes, just needs a modification of a few parameters |

| Manually reports defect statistics from production | Automated reporting that is always correct and accurate |

Automation options and industry 4.0

KINALI optical control systems provide data connection to any superior ERP or MES system. Our cameras respond precisely in the spirit of Industry 4.0 to the stimuli of other production nodes, can provide the results of their controls, provide statistics or automatically back up data.

The scalability of individual production nodes and their mutual connectivity brings higher efficiency and objective data from production. The advent of Industry 4.0 is becoming commonplace around the world. Those who get a head start in digitisation will be more competitive in globalised modern industry.

BENEFITS OF DIMENSION MEASUREMENT AUTOMATION

Financial savings

Have you calculated how much you spend on complaints per year? From now on, you can throw all your worries away.

Customer reputation

Your customers will always speak well of you.

Higher speed

Dimension control in the order of milliseconds versus long minutes when measuring at touch stations.

Identical products

Quality control automation ensures unifying defect evaluation metrics.

MENU

MENU